Our Process

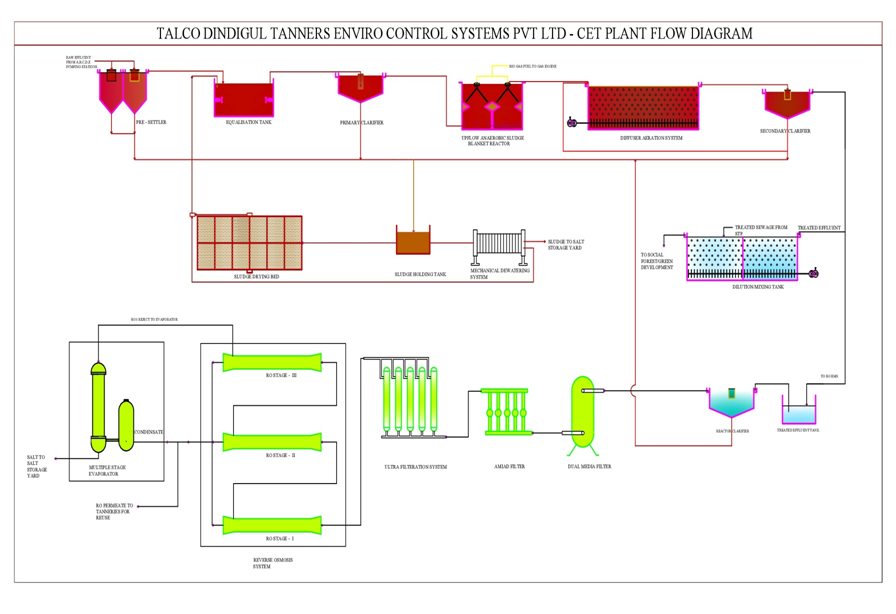

The effluent from the five pumping stations is pumped into a pre-settler and then to an equalization basin in the CETP. The treatment process in the DINTEC-CETP includes physio-chemical treatment, followed by two stage biological treatment. The treated effluent generally meets all parameters stipulated by the Tamilnadu Pollution Control Board (TNPCB), except for Total Dissolved Solids (TDS) which represents the salt (mainly chloride and sulphates) in the effluent. These salts are removed in the existing system and to improve treatment system facilities are being implemented under upgradation project.

With an aim to achieve all parameters of TNPCB including TDS and to minimize the drawl of fresh water from natural sources by the tanneries, the management of the Dindigul CETP (DINTEC) has initiated implementation of a Zero Liquid Discharge (ZLD) system by adopting RO for recovery of water from treated effluent and suitable evaporation for the management of saline reject from the RO system.

In addition to the ZLD process part of the treated effluent is mixed with Dindigul municipal corporation STP. The mixed effluent is utilized for the Social forestry developed with the interest to develop the environment.

Process Flow Diagram

Treatment System

Trade Effluent Treatment I (ZLD System)

The salient features of treatment and other control systems in CETP are given below :

Our CETP is comprised of conventional treatment units such as Equalization tank, Primary clarifier, Aeration tank, Secondary clarifier etc.

We are regularly upgrading our facility. A major Research and Development project of CSIR-CLRI entitled “Upflow Anaerobic Sludge Reactor with Sulfur Recovery system” has been implemented with financial support of Ministry of Environment, Forests & Climate Change (MoEF-CC), Ministry of Non-conventional Energy Sources (MNES) and Council for Scientific and Industrial Research (CSIR).

The membrane system for water recovery and Multi Effect Evaporator for reject management system is in use. This project was implemented with assistance from DIPP and GoTN.

Part of the Treated effluent is diluted with treated municipal sewage from Dindigul Corporation STP with adopting dilution ratio and standards prescribed by TNPC board. Diluted effluent with utilized for social forestry.